- thomaswyse

- New Member

Offline

Offline - Registered: 05-7-2022

- Posts: 13

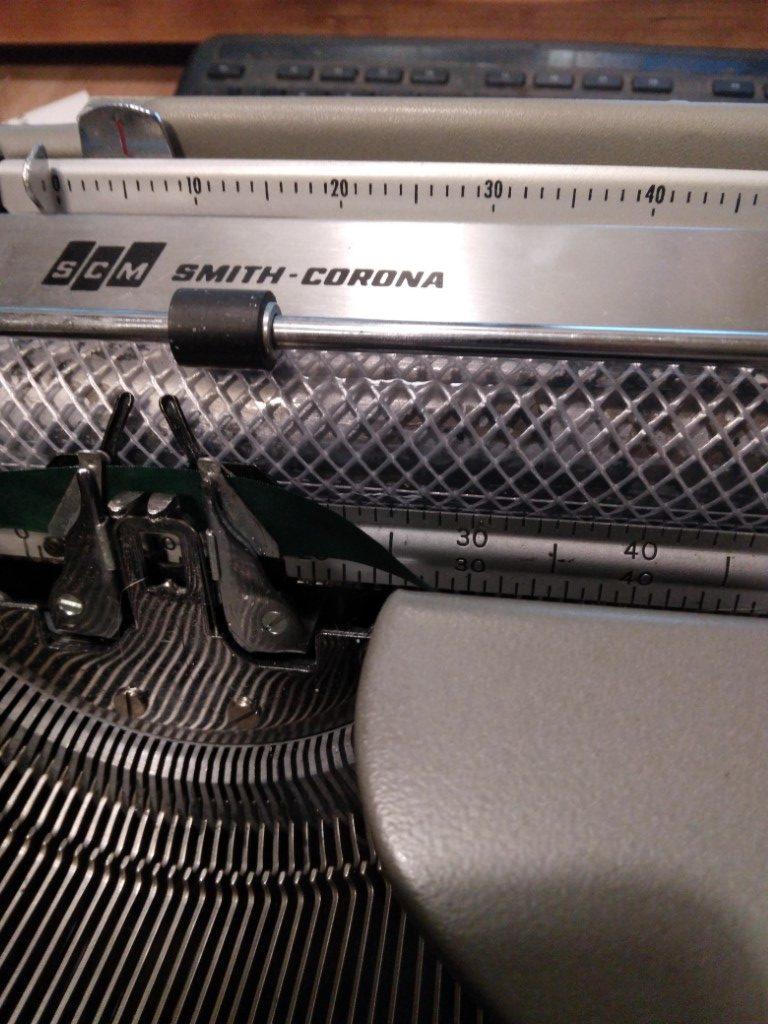

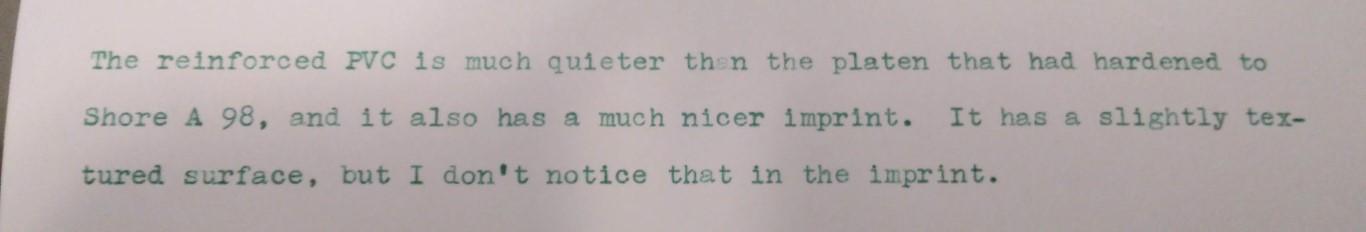

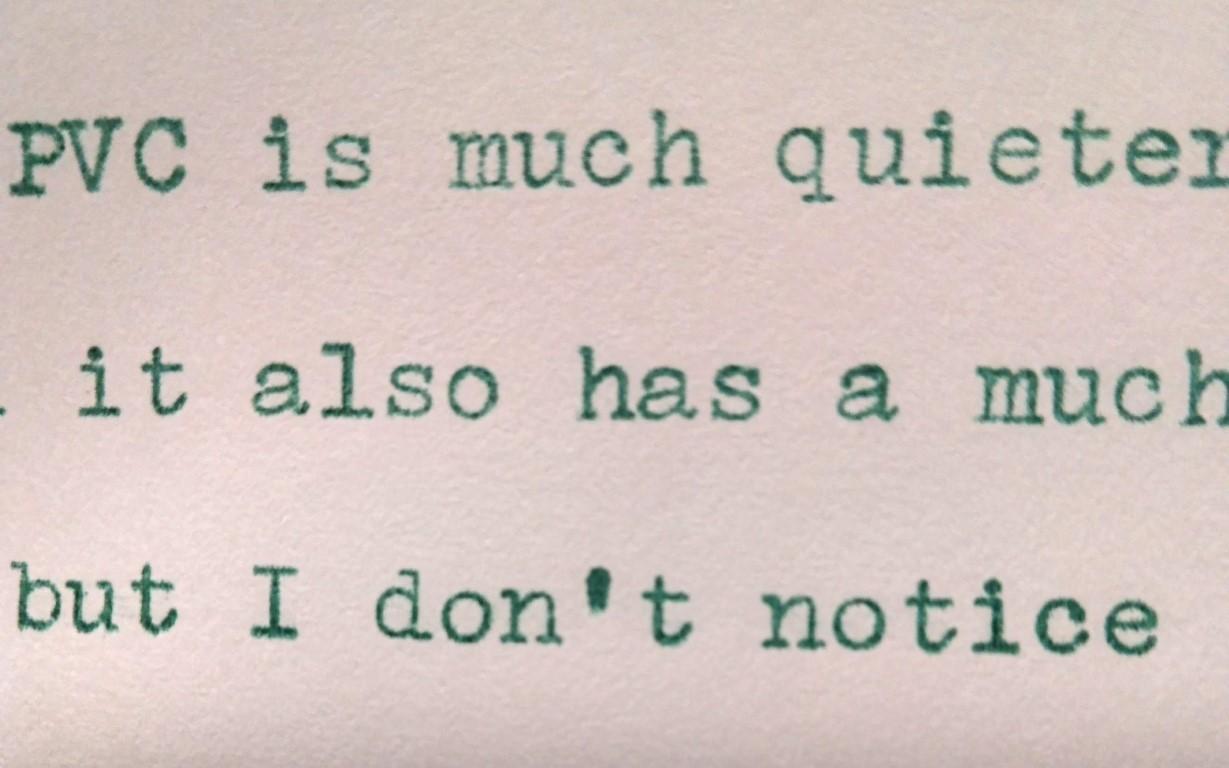

Hardware store PVC tubing on platen and Shore A readings

I see that some others have tried PVC tubing as a platen cover, but they didn't include hardness readings. I purchased an inexpensive digital Shore A durometer from Amazon. The platen on the SMC Sterling was 99.5 (I accidentally wrote the hardness of a different platen on the typing sample picture, and 98 is incorrect). I removed the platen material and replaced it with $3 worth of hardware store reinforced PVC with a 1" internal diameter. I used a heat gun to warm the PVC to slip in onto the platen core. It measures 80 to 83 Shore A. With two sheets of paper, it reads 86, and with Scotch single sided laminate it reads 89. It was interesting to see the similarity between the imprint of the durometer pin and the period. It is MUCH quieter, and it also has a much better imprint quality. I also like the aesthetics of the reinforced PVC. I used reinforced PVC because it was harder than non-reinforced PVC tubing.

I tried covering the platen with Fel-Pro 3019 Gasket material because I had some that I used to line the jaws of my woodworking vise. It was too soft, 69 to 73, and the letters embossed the paper.

My next experiment will be with some 90 durometer neoprene rubber sheet. I didn't find a source for 90 durometer tubing, so that's why I'll try the sheet and cement it on.

- robmck

- Speed Champion

Offline

Offline - From: Seattle, WA

- Registered: 31-1-2022

- Posts: 393

Re: Hardware store PVC tubing on platen and Shore A readings

Thanks for the experimentation and results. That's got a very post-modern look in an early-modern machine. Definitely would get conversation going at a type-in.

I've tried 90A rubber sheets from McMaster with mixed results. It worked better on some pica machines, but on other pica machines and the elite machines I tried, it was worse. Been meaning to do a systematic survey on several machines, but I've got a backlog of machines that need to be cleaned up.

- thomaswyse

- New Member

Offline

Offline - Registered: 05-7-2022

- Posts: 13

Re: Hardware store PVC tubing on platen and Shore A readings

Robmck, did you post about your experiments somewhere? I'm curious to know if you used several wraps of thin sheet or a single wrap of thicker material. If a single wrap, did you butt the edges, or did you feather out the edges and overlap? What were your worse results? Louder and a poorer imprint?

- •

- robmck

- Speed Champion

Offline

Offline - From: Seattle, WA

- Registered: 31-1-2022

- Posts: 393

Re: Hardware store PVC tubing on platen and Shore A readings

I used them as backing sheets and started to do a comparison between the Avery laminate sheet, a 90A, and an 85A rubber sheet. (Turns out I misremembered the durometer ratings). I was also trying different ribbons, too.

I dug up some of the test sheets I was using, shown below. (Caveat: These weren't intended for show, and neither typewriter had yet been cleaned up except for the type slugs, which is causing some of the spacing issues. Well, that and my typing way too fast at the time).

Below, the first sample is my KMM (12CPI) with an FJA Products nylon ribbon:

This is the Underwood Noiseless 77 referred to above (10CPI), which was using a Baco cotton ribbon.

(the occasional missing i's are due to a problem I've not yet been able to fix on this machine that the i typebar, and that typebar only, sometimes hits the type guide and fails to make an impression.)

I think the surprise I mentioned in the text was referring to the fact that rubber vs Avery showed so much less difference - at least with the cotton ribbon, which lays down a lot of ink.

As I said, I would really like to do a properly systematic test at some point on several machines, typeface sizes, and ribbons.

- robmck

- Speed Champion

Offline

Offline - From: Seattle, WA

- Registered: 31-1-2022

- Posts: 393

Re: Hardware store PVC tubing on platen and Shore A readings

Oh, and where I wrote 95A in the text, I was mistaken. Just checked the order and it's 90A.

Here are links to the parts:

Abrasion-Resistant Polyurethane Rubber Sheet, Semi-Clear, 12" Wide, 0.015" Thick | McMaster-Carr

Abrasion-Resistant Polyurethane Rubber Sheet, 12" Wide, 0.02" Thick | McMaster-Carr

- thomaswyse

- New Member

Offline

Offline - Registered: 05-7-2022

- Posts: 13

Re: Hardware store PVC tubing on platen and Shore A readings

Oh! I see. You used them as backing sheets. I plan to remove the platen rubber all together and rewrap the the platen with the rubber. A homemade platen replacement. It's hard for me to put $100 into a platen replacement on a typewriter that I paid $0 to $50 for. I'm a lot less squeamish about modifying typewriters than many people, and I enjoy the process. If it seems like the rubber wrap works on the "throw away" typewriter, then I'll do it good machines like my Adlers and Triumph. The only machine that I have with a reasonably soft platen is an Adler Tippa 1 that is 93A, and it's obviously softer and quieter. All the others are 98 to 99.5. My durometer only reads in half unit increments, and even on glass it reads 99.5. I was taken aback by what a difference it makes to go from 99.5 to 86 to 89. It's so much more pleasant from a noise, print quality and touch perspective. It does seem like it somehow changed the feel of the machine. Maybe a little snappier return? Maybe I'm making that up.

- •

- skywatcher

- Moderator

Offline

Offline - From: The Prairies of Alberta

- Registered: 14-3-2013

- Posts: 745

Re: Hardware store PVC tubing on platen and Shore A readings

Hi Thomas

One question I have about your interesting idea is the external diameter of the tubing vs the diameter of the original platen rubber. Did you need to make any ring and cylinder adjustments in order to get the proper type slug to platen clearance. Also, how well does this PVC tubing grip the paper. When it comes to those low-cost mechanical (not electronic) durometers, they do occasionally need recalibrating. Press the instrument onto a sheet of glass with 1 kg (2.2 lb.) force and set the dial to 100 against the needle (correction appreciated if required). When I got my durometer, I had to flush a few brass shavings out of the internal mechanism before the needle would do a smooth full-scale deflection sweep around the dial. All the best,

Sky

We humans go through many computers in our lives, but in their lives, typewriters go through many of us.

In that way, they’re like violins, like ancestral swords. So I use mine with honor and treat them with respect.

I try to leave them in better condition than I met them. I am not their first user, nor will I be their last.

Frederic S. Durbin. (Typewriter mania and the modern writer)

- thomaswyse

- New Member

Offline

Offline - Registered: 05-7-2022

- Posts: 13

Re: Hardware store PVC tubing on platen and Shore A readings

It's about 1 mm too big in diameter, so about 0.5 mm too close to the type slug. The paper drug on the slug when I checked it. I didn't adjust the ring and cylinder, though this machine has the eccentric nuts to do it. I plan to try chucking the platen into a drill and spin it through sandpaper to see how effective that is at reducing the diameter to see if that's a viable option for machines that don't have an easy ring and cylinder adjustment. I'll try some woodworking tools too. Sharp blades cut rubber quite well. At least the harder rubber. Maybe plane off the bulk of the excess and then make it close to perfectly cylindrical chucked in the drill.

The durometer is digital. It reads 99.5 on glass. It can be zeroed, and it looks like there is a way to adjust it under the cap on the top of the machine, but there aren't instructions to adjustment. I figure that 99.5 is close enough to 100 to not mess with it. At least not for my purposes, especially when it only reads to half a number.

- •

- thomaswyse

- New Member

Offline

Offline - Registered: 05-7-2022

- Posts: 13

Re: Hardware store PVC tubing on platen and Shore A readings

Oh, the grip on the paper is better than a hard platen!

- •

1 of 1

1 of 1