- ztyper

- Key Master

Offline

Offline

- From: Somewhere in New Jersey

- Registered: 01-10-2014

- Posts: 773

DIY Platen Recovery

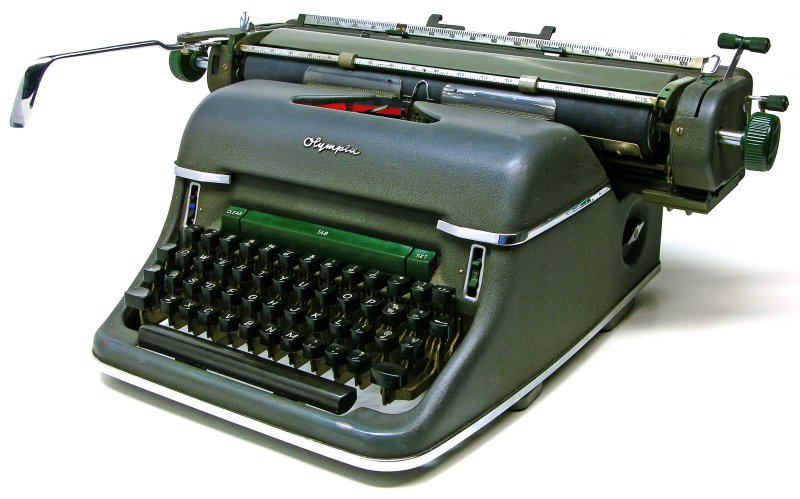

I really need to make ALL of my platens softer. They are all hard as rock and take a toll on everything in the typewriter. Especially my Olympia SM-4 platen. Is there any household solution that can soften up the platen? I don't have the money to get it replaced professionally and rubber tubing is out of the question. So really any thing is valuable to me.

A high schooler with a lot of typewriters. That's pretty much about it.

- Uwe

- Moderator

Offline

Offline

- From: Toronto, Canada

- Registered: 12-3-2013

- Posts: 4,410

Re: DIY Platen Recovery

I use rubber rejuvinator spray which can be bought for less than $10 a can. Look for the stuff online. You have to be careful not to get it on any other part of the machine like the case's paint, but otherwise it does a good job of cleaning the platen and softening the rubber enough.

The pronoun I has always been capitalized in the English language for more than 700 years.

- malole

- Inactive Account

Offline

Offline

- From: East Anglia, UK

- Registered: 02-6-2014

- Posts: 330

Re: DIY Platen Recovery

This reminds me that I had no luck finding any good rubber rejuvinator online in the UK this summer. I found a roller spray which did nothing at all, meant for printer rollers but it was all I could find. I just had another search and came up with a rubber sealant rejuvinator stick. I'm thinking it might be easier to apply to a platen than a spray. So I'll let you know how it goes.

- Ektagraphic

- Touch Typist

Offline

Offline

- From: Mass.

- Registered: 05-10-2014

- Posts: 146

Re: DIY Platen Recovery

Perhaps I'll give this route a try first. I've never tried this. Great idea. Thanks!

- JustAnotherGuy

- Speed Champion

Offline

Offline

- From: Illinois, USA

- Registered: 20-9-2014

- Posts: 277

Re: DIY Platen Recovery

All but two of my 20 something machines have pretty hard platens. I think ill give the spray a shot..

- ztyper

- Key Master

Offline

Offline

- From: Somewhere in New Jersey

- Registered: 01-10-2014

- Posts: 773

Re: DIY Platen Recovery

I'll try the spray too. I found one onlline, but I didn't order it for some reason. Weird...

A high schooler with a lot of typewriters. That's pretty much about it.

- •

- TypewriterGuy

- Typewriter Talk Vet

Offline

Offline

- From: United States

- Registered: 24-4-2015

- Posts: 1,250

Re: DIY Platen Recovery

I just tried this on my feed rollers (Which were absolutely rock hard and would not grip ANYTHING) and it works great! The cheapest thing you can do is use heat shrink tubing.

First, sand about a millimeter off of your desired rubber roller.

Then fit a heat shrink tubing tube around the roller, and make sure there is about a half cm to 2 cm depending on the size of the roller sticking out of each side.

Then, use a heat gun (Or blow dryer) and heat up the tubing, watch as it shrinks, and turn off the heat gun.

Trim the edges, and tada! DIY recovered roller! Much MUCH cheaper than getting it re rubbered. And the results are much better than the spray (To me), because it is like a new layer of rubber. Of course, you can layer the entire thing to make new rubber, but this is easiest.

Back from a long break.

Starting fresh with my favorite typer. A Royal Futura!

- Repartee

- Key Master

Offline

Offline

- From: Brooklyn

- Registered: 12-10-2015

- Posts: 683

Re: DIY Platen Recovery

The heat shrink tubing I'm familiar with is thin-walled and slick finished, and does not look like it would be useful for recovering rubber. But maybe this is something more like...

I ordered a box for possible repair of D-shaped feed rollers on a Remington portable - they are going to require more aggressive grinding down to a cylindrical shape, and several layers of tubing!

"Damn the torpedoes! Four bells, Captain Drayton".

- TypewriterGuy

- Typewriter Talk Vet

Offline

Offline

- From: United States

- Registered: 24-4-2015

- Posts: 1,250

Re: DIY Platen Recovery

The heat shrink I used has a rubbery surface, and besides, better than having the feed rollers rock hard and smooth!

Back from a long break.

Starting fresh with my favorite typer. A Royal Futura!

- Repartee

- Key Master

Offline

Offline

- From: Brooklyn

- Registered: 12-10-2015

- Posts: 683

Re: DIY Platen Recovery

Oh, I think it's a great idea! Just noting I would not have thought of it because the kind I was familiar with was unsuitable. You have broadened my heat shrink tubing horizon. ![]()

![]()

Now, I was intending to take another photo, and upload it to Photobucket, and... I'll take the lazy approach and just change the topic here, because you are as likely to have a good idea as anybody:

I got the carriage off an Underwood 3, and exposed the jammed feed roller release mechanism underneath. The means of pressing the rollers against the platen and releasing them involved two parallel shafts some kind of cams... bottom line, between the two shaft there must be at least 10 bearing surfaces. So big surprise - mechanism is frozen hard. I've put some mineral spirit on the bearings, and tapped them, and some more spirits, and some more tapping... and I am not getting anywhere. Any thoughts?

"Damn the torpedoes! Four bells, Captain Drayton".

1

1