I tried to leave the machine, except the obvious dirt in the original state. The most work went into the mechnical overhaul. I completly removed the carriage and types, as there was a decent amount of old dust, debris which seemed like somone was drilling holes into a wall with dust falling into the machine and a lot of old oil.

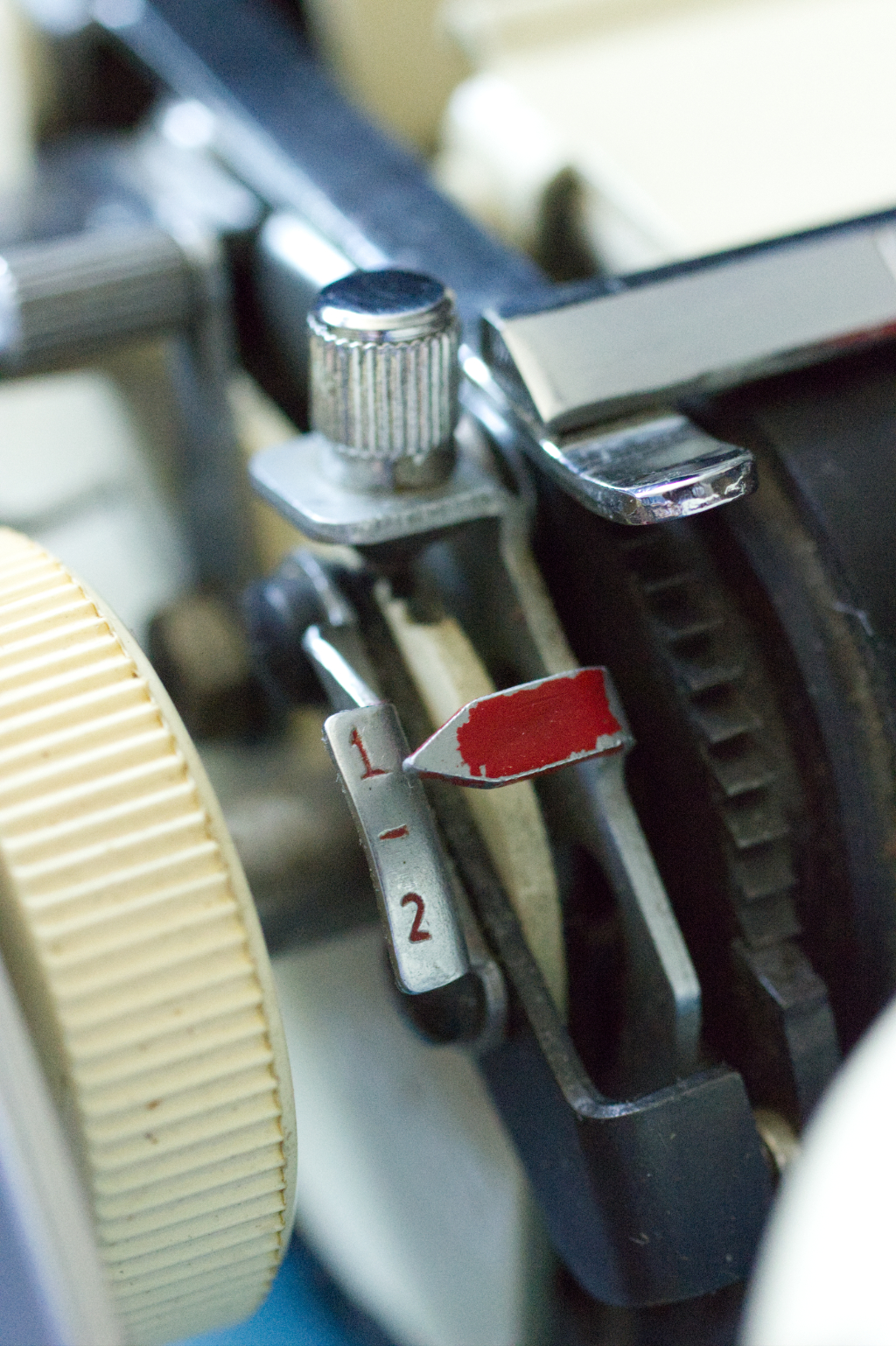

In my opinion the typewriter is very nice for a first oberhaul als the types are numbered and the rods connecting the types to the key levers can be easily sorted by direction of the hooks at the end facing the keys and the length.

I used a metal ruler to hang the rods and except one, which was bend and therefore seemed smaller, all were in perfect order. The layout of the rods is 22/22 means they are mirrored based on the numbers of the types.

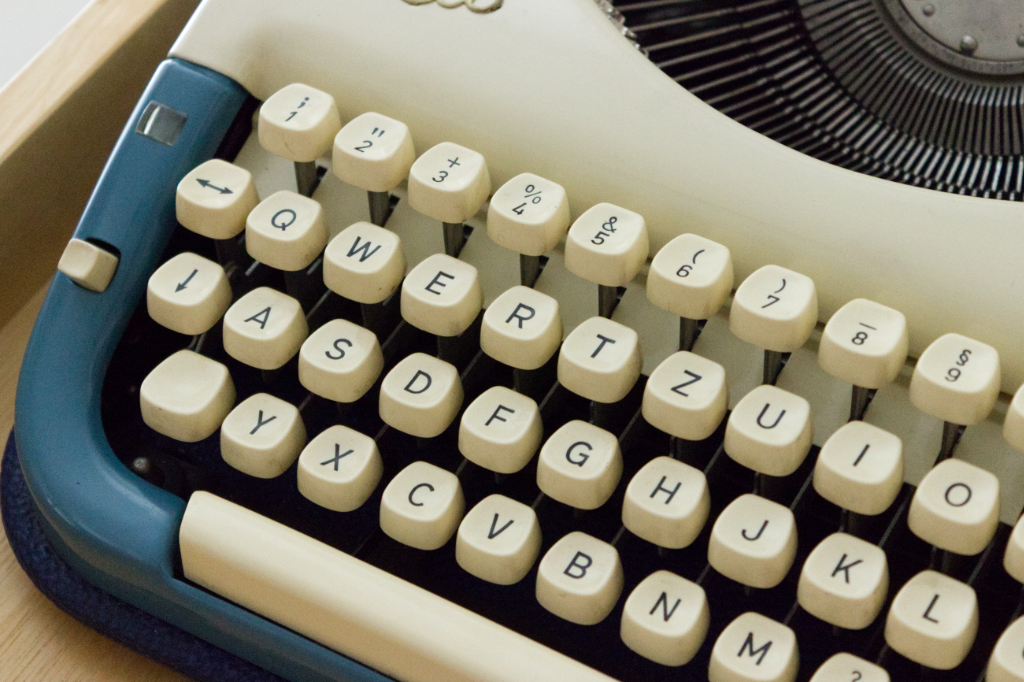

I would suggest not to remove the springs which pull back the keys. Its a bit tricky to reassemble them and unless there is really a lot of dirt its ok the remove the oil with enough proper solvent and some towels underneath.

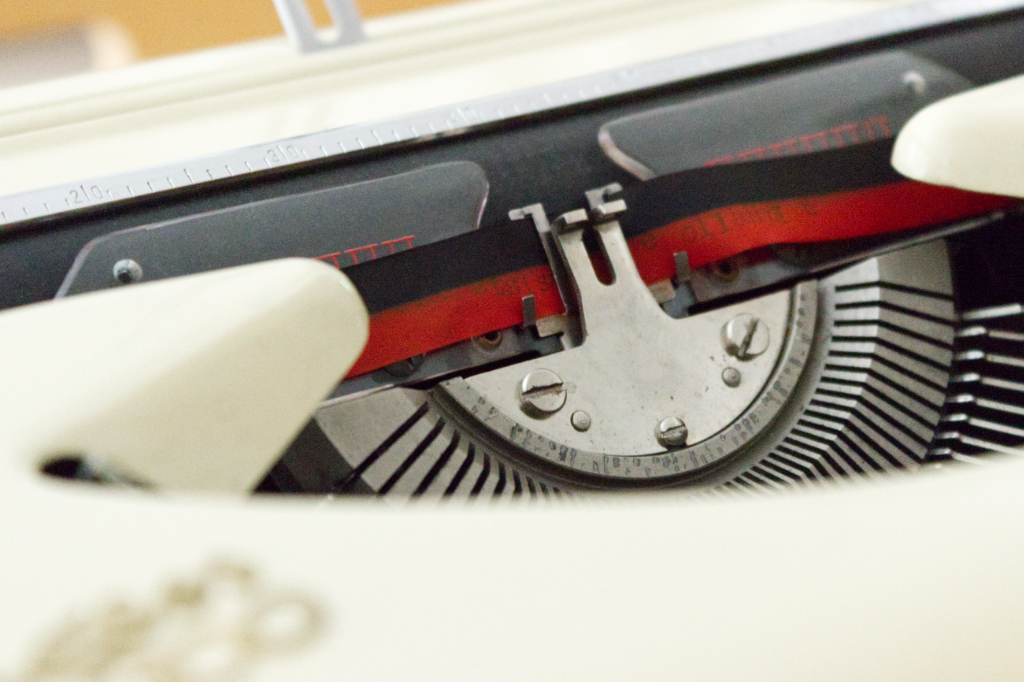

The design of the carriage bearing is smart, but not so easy to assemble. You have to be careful as they come off when you pull the carriage out. They are on kind of sled. For disassembly you first have to find the plastic band which is running from the spring to the left and into a hole close to the knob to turn the platen on the right side. There is one part down where you can insert this as otherwise the sprin pulls it back and unwinds. As the spring is most lickly loosening some of its strength over time i suggest to pre tension the spring 2-3 turns. This fixes the problem, that at the end the carriage of my machine was too weak to overcome the resistance from the bell lever.

To reassemble the bearings an carriage you have to imagine that the carriage at the far left and right positions is completly supported by the bearings on the rails inside the machine. So the bearing sleds have to be fully inside the machine. Thats how I got it to work. Be careful as the metal which the sleds are made off is thin.