1 2 Jump to

1 2 Jump to

| Maintenance & Repairs » Hardware store PVC tubing on platen and Shore A readings » 21-9-2022 13:08:07 |

- thomaswyse

- Replies: 8

-

Oh, the grip on the paper is better than a hard platen!

| Maintenance & Repairs » Hardware store PVC tubing on platen and Shore A readings » 21-9-2022 13:07:17 |

- thomaswyse

- Replies: 8

-

It's about 1 mm too big in diameter, so about 0.5 mm too close to the type slug. The paper drug on the slug when I checked it. I didn't adjust the ring and cylinder, though this machine has the eccentric nuts to do it. I plan to try chucking the platen into a drill and spin it through sandpaper to see how effective that is at reducing the diameter to see if that's a viable option for machines that don't have an easy ring and cylinder adjustment. I'll try some woodworking tools too. Sharp blades cut rubber quite well. At least the harder rubber. Maybe plane off the bulk of the excess and then make it close to perfectly cylindrical chucked in the drill.

The durometer is digital. It reads 99.5 on glass. It can be zeroed, and it looks like there is a way to adjust it under the cap on the top of the machine, but there aren't instructions to adjustment. I figure that 99.5 is close enough to 100 to not mess with it. At least not for my purposes, especially when it only reads to half a number.

| Maintenance & Repairs » Hardware store PVC tubing on platen and Shore A readings » 20-9-2022 13:44:40 |

- thomaswyse

- Replies: 8

-

Oh! I see. You used them as backing sheets. I plan to remove the platen rubber all together and rewrap the the platen with the rubber. A homemade platen replacement. It's hard for me to put $100 into a platen replacement on a typewriter that I paid $0 to $50 for. I'm a lot less squeamish about modifying typewriters than many people, and I enjoy the process. If it seems like the rubber wrap works on the "throw away" typewriter, then I'll do it good machines like my Adlers and Triumph. The only machine that I have with a reasonably soft platen is an Adler Tippa 1 that is 93A, and it's obviously softer and quieter. All the others are 98 to 99.5. My durometer only reads in half unit increments, and even on glass it reads 99.5. I was taken aback by what a difference it makes to go from 99.5 to 86 to 89. It's so much more pleasant from a noise, print quality and touch perspective. It does seem like it somehow changed the feel of the machine. Maybe a little snappier return? Maybe I'm making that up.

| Maintenance & Repairs » Hardware store PVC tubing on platen and Shore A readings » 20-9-2022 05:59:59 |

- thomaswyse

- Replies: 8

-

Robmck, did you post about your experiments somewhere? I'm curious to know if you used several wraps of thin sheet or a single wrap of thicker material. If a single wrap, did you butt the edges, or did you feather out the edges and overlap? What were your worse results? Louder and a poorer imprint?

| Maintenance & Repairs » Hardware store PVC tubing on platen and Shore A readings » 19-9-2022 20:39:18 |

- thomaswyse

- Replies: 8

-

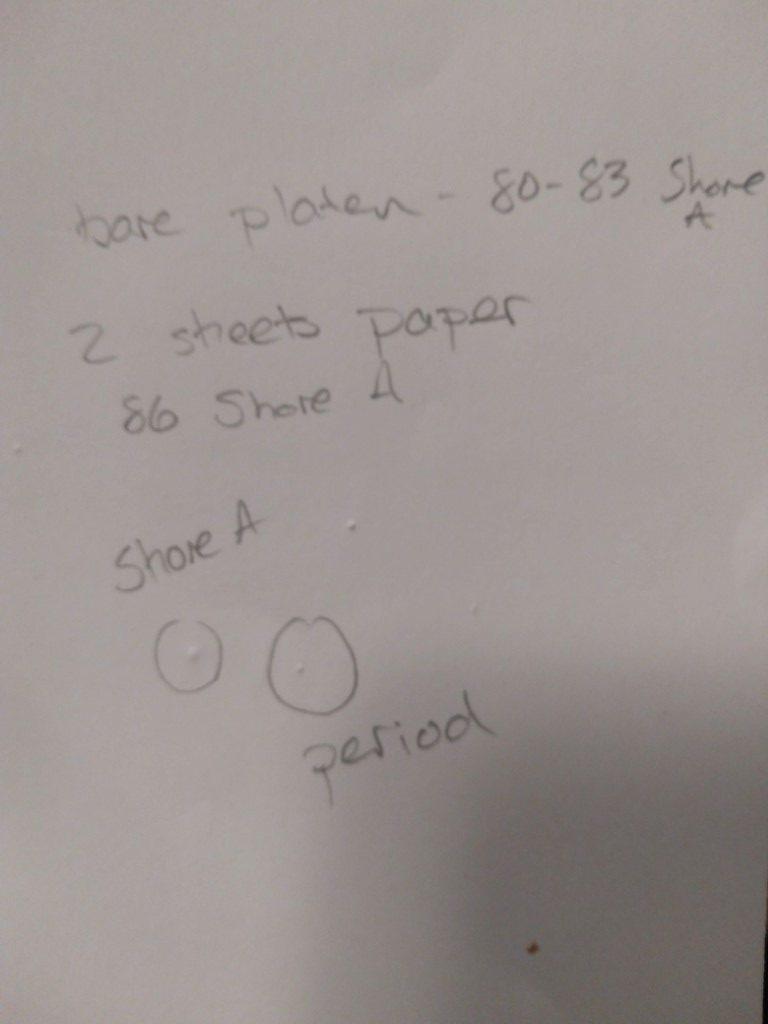

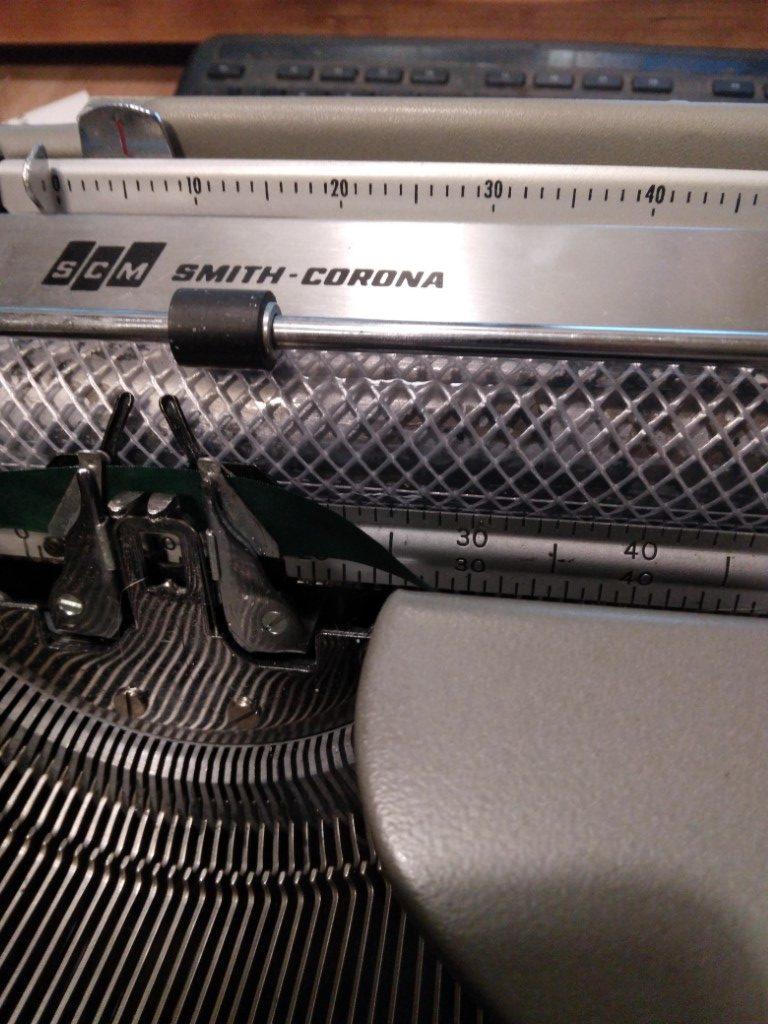

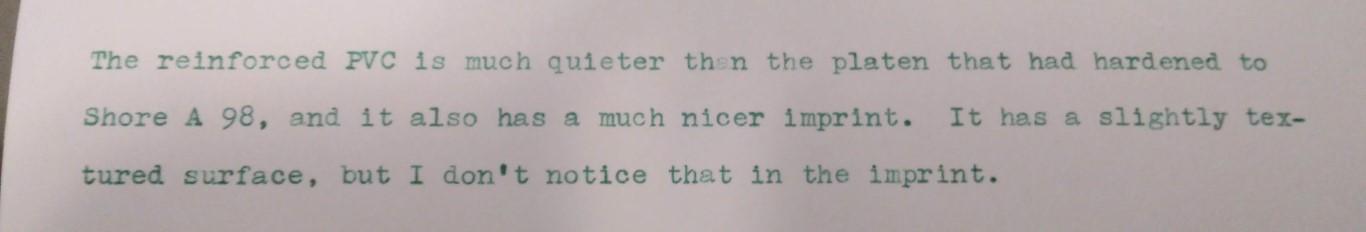

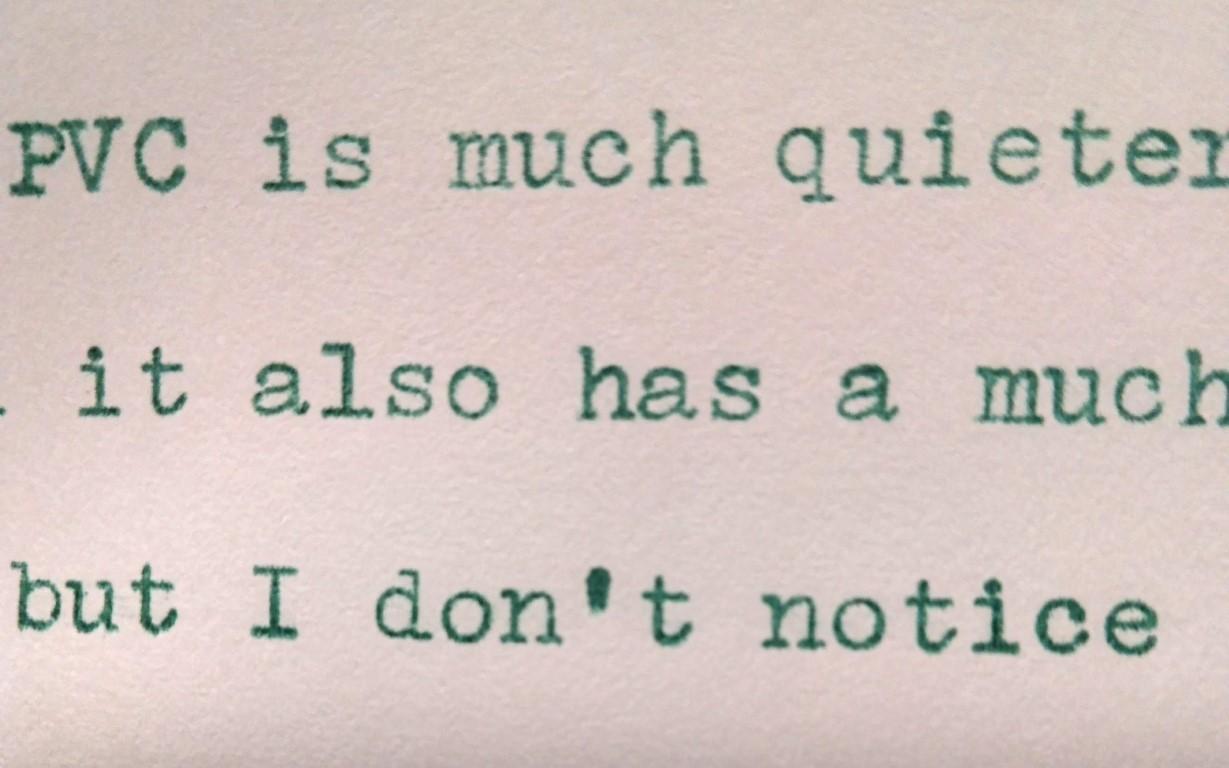

I see that some others have tried PVC tubing as a platen cover, but they didn't include hardness readings. I purchased an inexpensive digital Shore A durometer from Amazon. The platen on the SMC Sterling was 99.5 (I accidentally wrote the hardness of a different platen on the typing sample picture, and 98 is incorrect). I removed the platen material and replaced it with $3 worth of hardware store reinforced PVC with a 1" internal diameter. I used a heat gun to warm the PVC to slip in onto the platen core. It measures 80 to 83 Shore A. With two sheets of paper, it reads 86, and with Scotch single sided laminate it reads 89. It was interesting to see the similarity between the imprint of the durometer pin and the period. It is MUCH quieter, and it also has a much better imprint quality. I also like the aesthetics of the reinforced PVC. I used reinforced PVC because it was harder than non-reinforced PVC tubing.

I tried covering the platen with Fel-Pro 3019 Gasket material because I had some that I used to line the jaws of my woodworking vise. It was too soft, 69 to 73, and the letters embossed the paper.

My next experiment will be with some 90 durometer neoprene rubber sheet. I didn't find a source for 90 durometer tubing, so that's why I'll try the sheet and cement it on.

| Maintenance & Repairs » Quiet Loud Smith Corona Electrics by Slowing Power Roll » 19-9-2022 19:54:48 |

- thomaswyse

- Replies: 8

-

Dang! It looks great! Is the space bar the original color?

| Portable Typewriters » Triumph Perfekt De JUR conical frame pins » 14-9-2022 08:30:43 |

- thomaswyse

- Replies: 6

-

Pete, I found it was easy enough to change the touch on my Perfekt De Jur with some fiddling. I don't know what your background or comfort level is with making modifications, so maybe you've already considered this. I do a lot more monkeying than my knowledge or skill warrants, but I enjoy learning. I wanted to make the touch lighter, so I made a little link out of a staple and inserted the new link at the top of the universal bar return spring. The spring attaches under the right ribbon spool. It was easier to do with the body off the machine. If the link is too long then the ribbon vibrator won't drop all the way because it has a mechanism that works opposite the universal bar.

Unfortunately, the bar that holds all the springs between the key levers and type bars isn't adjustable like it is on some machines. I plan to add some length to those springs or modify the machine to allow adjustment at some point to see what difference it makes in the feel of the machine. I really like how it types, but I have a hard time not wanting to modify and adjust things even if I ultimately return to the factory settings.

| Maintenance & Repairs » Quiet Loud Smith Corona Electrics by Slowing Power Roll » 10-9-2022 08:46:16 |

- thomaswyse

- Replies: 8

-

Great. Thank you. How much reduction in the loudness of the slugs hitting the platen and change in letter embossing did you notice? It was surprisingly noticeable the way I did it. It went from being unpleasant to use because of the noise and heavy embossing on the backer sheet to just being a normal, hard platen typewriter noise with very little embossing.

| Maintenance & Repairs » Quiet Loud Smith Corona Electrics by Slowing Power Roll » 09-9-2022 21:25:36 |

- thomaswyse

- Replies: 8

-

Good to know. The O-rings must change the gear ratio some too since they are a different width than the belts.

| Maintenance & Repairs » Quiet Loud Smith Corona Electrics by Slowing Power Roll » 09-9-2022 18:47:32 |

- thomaswyse

- Replies: 8

-

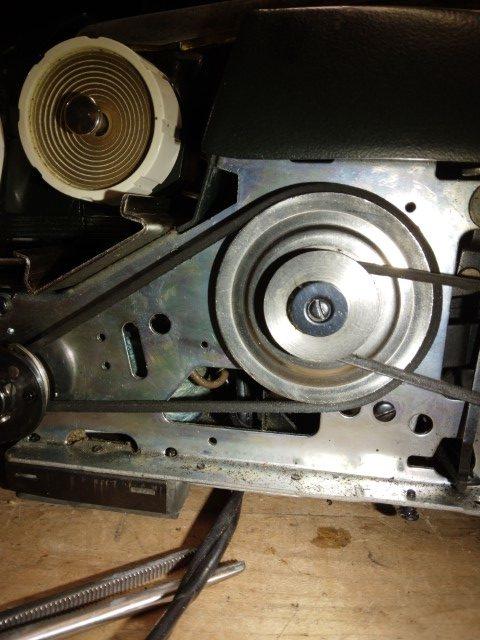

I wanted to reduce the noise and the paper embossing on my Sears Medalist Electric 12 without recovering the platen. This should work on many Smith Corona electrics. This changes the gear ratios and slows the power roll. It's possible to make it so slow that the keys make a faint impression when the shift is enabled.

Remove the body and belts. Remove the small bolt/washer/felt that holds the double pulley in place. Hold the large side of the double pulley in a padded vise and use a parallel jaw pliers to pinch the two sides closer together. Use a spacer of your devising if you want to have precise width.

Take the pulley out of the vise and insert a screwdriver between the two haves of the small pulley sides. Gently twist the screwdriver to force the pulley halves apart. It's easy to see your progress and control the amount of spread.

Reinstall the parts and give it a try before you put the body back on. It's possible to make the large pulley too narrow and the small pulley so wide that the belt will drop too far into the vee and get caught in the parallel sides of the pulley stalling the machine. It's easy enough to push them back together and then peen bushing that the pulleys are on to hold it in if you go too far. The picture below shows how my belts ride in the pulleys. It's still possible to use the copy set knob with this setup.

1 2 Jump to

1 2 Jump to